-40%

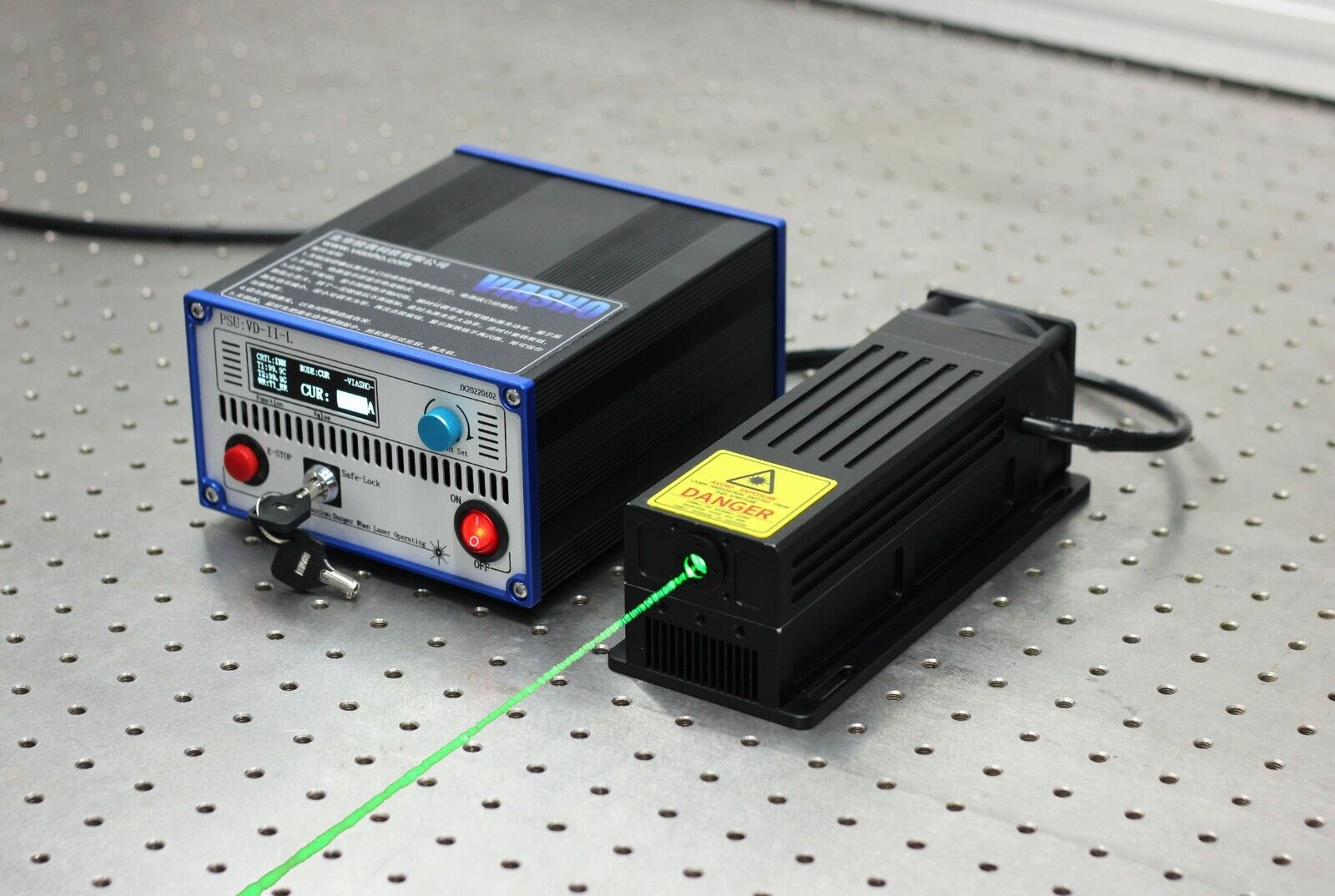

Viasho 532nm 4W green laser,both TTL/analog mode, stable output, bright

$ 1477.87

- Description

- Size Guide

Description

This is a compeleted new4

W green laser. And we make some new design and change the power supply to a digital version which can supply better modulations and make the laser more stable.

OK.If you have any question,please leave a message,then I will answer you in time.

Please see specs below:

Wavelength (nm)

532

Output Power (mW)

4000

Working Mode

CW

Beam Mode

Transverse

TEM00

Longitude

Multi-longitude

Spectral Linewidth (nm)

<0.1

Polarization

Line polarization

Polarization Ratio

>100:1

Beam Quality (M2 factor)

<1.2

Beam Divergence (full angle, mrad)

1.5

Beam Diameter at Aperture (mm)

2.5

Beam Roundness

>90%

Power Stability (RMS, over 8 hours)

<5%

Aperture Position (mm)

50

Laser Head

Dimensions (L×W×H, mm)

205x60x50

External Modulation

5V TTL/5V Analogue

Modulating Repetition

30KHz TTL/10KHz Analogue

Cooling System

TEC

Warm-up Time (minutes)

<15

Operation Temperature (

℃

)

18~30

Expected Lifetime (hours)

>10000

Warranty Time

1 year

1.

Product

VA series laser driver power supply with high power semiconductor laser constant current drive, dual TEC temperature control and system monitoring functions, which uses a constant-current PWM closed-loop laser driver, PWM temperature control and intelligent MCU central control system, so as to LD lasers provide efficient and reliable drive and temperature control, suitable for driving a variety of air-cooled solid-state lasers or laser module.

1.1.

Feature

Ø

PWM constant current technology, more efficient

Ø

TEC dual output, flexible and accurate temperature control

Ø

overheating, over

current, overvoltage, soft start multiple protection

Ø

A key jog buttons, the user interface is simple and easy to operate,

Ø

S

mall size, light weight

Ø

I

nternal / external control mode selection

1.2.

Specification

Model

VD-IA

/ VD-1B

LD drive current

0

~

10A

LD voltage

2

~

18V

adaptive

Modulation

Continuous / analog (external control) / Digital (external control)

TEC Temperature Range

16.0

~

28.0

℃

TEC maximum drive voltage

20V

Maximum drive current TEC

6A

Rated voltage

90

~

240V AC

Operating ambient temperature

-10

~

45

℃

Dimensions (L × W × H)

168mm

×

16

4mm×

80mm

Total weight

2.0kg

1.3.

Dimensions

(mm)

1.4.

Front view

1

Vents

,

for ventilation;

2

Display options

,

two green LED digital display, such as C1

.

3

V

alues

,

three red LED digital display, such as 5.58

.

4

Rotary

S

witch

, y

ou can smooth, counterclockwise rotation of options selected performance parameters change

, p

ressing the mode selection.

LED display mode

follow as,

(1) Normal mode,

screen never

blink, turn counterclockwise options forward flip, back flip clockwise options. Press once to enter the setup mode or exit the setup mode.

(2)

S

etting mode, the value

is

blink

ing

, turn counterclockwise

or

clockwise to reduce

or increase

property value.

(3)

A

larm mode

,

options flashes and displays the corresponding property value. Rotary switch temporarily lapsed in this state.

Detailed display described later.

1.5.

Back view

1

DB15 (pin) Interface

, connect to

the laser

head.

2

Cooling fan

for

ventilation

.

3

DB15 (hole) interfaces

,

external control signal input;

4

T

hree-pin

p

ower

socket (L, N, PE).

5

Interlock, safety lock protection.

6

Power switch: on / off external power supply.

Interface definition

as follows.

(

1

)

DB25

Interface

definition

No.

Pin name

Description

No.

Pin name

Description

1

LD1+

L

aser positive

14

LD1+

L

aser positive

2

LD1+

L

aser positive

15

R

t

2-

T

hermistor

2

negative

(Internal ground)

3

Fan-

Fans negative

16

Rt2+

T

hermistor

2

positive

4

TEC2-

C

ooler

2

negative

(Internal ground)

17

TEC1-

C

ooler

1

negative

(Internal ground)

5

TEC2-

C

ooler

2

negative

(Internal ground)

18

TEC1-

C

ooler

1

negative

(Internal ground)

6

NC

No connection

19

Fan+

Fans

positive

(

Internal

+

24V

)

7

TEC1+

C

ooler

1

positive

20

RT2+

T

hermistor

2

positive

8

TEC1+

C

ooler

1

positive

21

RT2-

T

hermistor

2

negative

(Internal ground)

9

TEC2+

C

ooler

2

positive

22

Rt1+

T

hermistor

1

positive

10

TEC2+

C

ooler

2

positive

23

Rt1-

T

hermistor

1

negative

(Internal ground)

11

Rt1+

T

hermistor

1

positive

24

Rt1-

T

hermistor

1

negative

(Internal ground)

12

LD1-

Laser

negative

25

LD1-

Laser

negative

13

LD1-

Laser

negative

(

2

)

DB15

Interface definition

No.

Pin name

Description

No.

Pin name

Description

1

NC

No connection

9

NC

No connection

2

GND

Ground

10

NC

No connection

3

NC

No connection

11

NC

No connection

4

GND

Ground

12

NC

No connection

5

+5Vout

+5V

output

13

NC

No connection

6

Signal-

Negative signal input

(Internally grounded)

14

NC

No connection

7

NC

No connection

15

Signal+

Signal Input Positive

8

NC

No connection

Note: +5 V output current is less than 0.5A, non-shorted.

2.

Handling and storage

(1)

H

andling

gently

to avoid

violent collisions

.

P

ut the device in the box

w

hen long-distance transport

.

(2)

S

tored in a cool dry place, away from water and corrosive substances.

3.

Installation and debugging

(1)

W

hen the floating installation, to ensure that the fixed hanger strong enough. Do not live installation.

(2) When debugging, check the wiring is correct, the power supply is consistent, then everything is ready on power debugging.

4.

How to use

4.1.

Wiring

After the power supply using panel wiring, DB25 interfaces connected to the laser, DB15 interfaces to the external (when the internal time to pick), power outlet plug the power cord.

4.2.

Power on/off

Slide the power switch can be turned on or off.

S

tep

1,

LED display full brightness

and

all off three times, the buzzer rang three times. Then start by setting parameters to save power.

Step

2,

d

isplay Machine Model Vd-3A.

S

tep

3,

display program version number, such as [01120]

. The first

two LED display the

version

of

the display unit, after three [120] for the control unit version number.

Note: The power supply must be confirmed prior to initial use of the laser power setting parameters and supporting adaptation

.

LD maximum operating current value

must be

set correct

ly,

otherwise it may cause permanent damage to the laser or power.

4.3.

Display and settings

4.3.1.

Display when client mode

Options

Range

Description

Settings

【

C1

】

【

0

.

00

】~【

12.0

】

LD

current

,

the unit

A

Enabled

【

A2

】

【

0

】~【

99.9

】

TEC1

actual temperature value, the unit

℃

Disabled

【

A4

】

【

0

】~【

99.9

】

TEC2

actual temperature value, the unit

℃

Disabled

【

EI

】

【

I

】

/

【

O

】

Mode, [O]

is

the external control mode, [I]

for

the internal control mode

Enabled

【

Pd

】

【

100

】~【

200

】

If the password is correct, the display [ON] to exit and enter expert mode status;

If the password is wrong, after exiting the display [OFF], and in client mode state.

Enabled

Password input

4.3.2.

Display when expert mode

Options

Range

Description

Settings

【

C1

】

【

0.20

】~

Max.

LD

current, the unit

A

Enabled

【

U1

】

【

0.0

】~【

12.0

】

LD voltage in V

Disabled

【

A1

】

【

16.0

】~【

28.0

】

TEC1 set temperature value, unit

℃

Enabled if correct password

【

A2

】

【

0.0

】~【

99.9

】

TEC1

actual temperature value, the unit

℃

Disabled

【

U2

】

【

0.0

】~【

30.0

】

TEC1 voltage value, unit V

Disabled

【

A3

】

【

16.0

】~【

28.0

】

TEC2 set temperature value, unit

℃

Enabled if correct password

【

A4

】

【

0.0

】~【

99.9

】

TEC2 actual temperature value, the unit

℃

Disabled

【

U3

】

【

0.0

】~【

30.0

】

TEC2 voltage value, unit V

Disabled

【

EI

】

【

I

】

/

【

O

】

Mode, [O]

is

the external control mode, [I]

for

the internal control mode

Enabled

【

U4

】

【

0.00

】~【

5.00

】

Input signal voltage value, unit V

Disabled

【

A5

】

【

0.0

】~【

99.9

】

Board temperature value, unit kΩ

Disabled

【

Lc

】

【

6.00

】~【

12.0

】

LD current limit, Unit A

Enabled if correct password

【

b1

】

【

0.20

】~【

3.00

】

LD bias current setting (external control mode), Unit A

Enabled if correct password

【

Pd

】

【

100

】~【

200

】

If the password is correct, the display [ON] to exit and enter expert mode status;

If the password is wrong, after exiting the display [OFF], and in client mode state.

Enabled

The initial state of the power

on is

client mode.

Note: When you modify LD current limit, it will automatically be transferred to the minimum operating current. Therefore, the revised LD current limit, need to re-set the operating current.

4.3.3.

P

riority alarm display

When the display control unit receives the alarm signal immediately display the value of options and performance alarms,

blink

ing options. If there are several functions simultaneously warning appears, indicating higher priority options. The priority of each function:

【

C1

】

>

【

U1

】

>

【

A1

】

>

【

A2

】

>

【

U2

】

>

【

A3

】

>

【

A4

】

>

【

U3

】

>

【

EI

】

>

【

U4

】

>

【

A5

】

>

【

Lc

】

>

【

b1

】

4.3.4.

Setting m

e

t

hod

Display properly, turn counterclockwise options forward flip, back flip clockwise options.

Press once to enter the setup mode or exit the setup mode.

When you enter the setup mode, the performance value flashes, turn counterclockwise

or clockwise

to reduce

or increase

property value

.

I

f rotary switch is turned fast,

there is

a wide range

change

of rapid acceleration / deceleration.

Items

enabled

can only be set.

5.

M

aintenance

(1) Keep the power to work in a dry, ventilated, dust-free environment.

(2) When using the rotary switch, do not use too much force, the rotary switch broke.

(3)

P

eriodically check external wiring connections, whether there is loosening.

(4) When a fault occurs, disconnect the power supply to the service personnel, not repaired before reuse.

6.

F

ailure Analysis and Troubleshooting

Symptom

Failure Analysis

Troubleshooting

No display

AC power cord is not plugged

Tighten or replace wire power cord

Power switch is not turned

Slide the panel power switch is ON

R

otary switch

cannot set

initialization state in the state

Self-test and initialization state does not allow the state to set

Is not allowed to set function

This is not a problem

Alarm status

Eliminate excessive corresponding parameter

C1 shows 0

No laser current

Check the DB25 connector is loose

C1 flashing

Over

current

Power supply is damaged, repair

A2

flashing

Laser thermal protection

Check the laser fan is normal

A4

flashing

Laser thermal protection

Check the laser fan is normal

A5

flashing

Power overheating

Check the power supply fan is normal

Outlet is blocked

No external modulation output

DB15 interface plug is not connected

Check the DB15 connector and seated

Mode setting error

Modify the operating mode